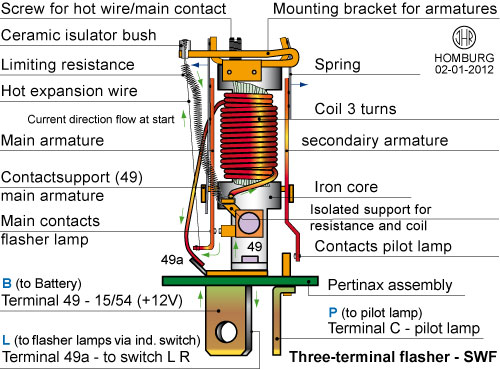

Hot-wire flasher unit

In most NSU cars, the hot-wire three-terminal

flasher relay was mounted as direction indicator.

Made by Bosch, Hella or SWF.

The flasher unit makes and breaks the current flow to the front and rear amber indicator lamps at a frequency of between 60 and 120 flashes per minute.

The principle of operation

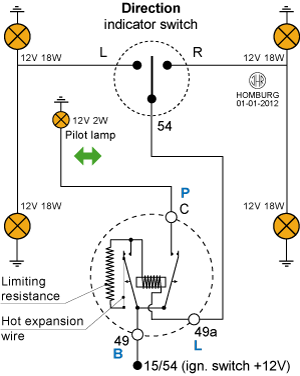

When the direction indicator switch is on (the main lights contact gap starts at 0,3 mm) current flows through the heater wire, the resistor and the coil. As the heater wire expands, the main armature moves under spring tension to close the main contacts. During heating the limiting resistance prevents lighting of the indicator lamps, but when the contacts close this resistance is short-circuited and connects the indicator lamps straight on to the 12 volt supply via the coil.

The higher current in the coil the magnetises the iron core and attracts the armature so that the contacts close firmly. This magnetism also attracts the secondairy armatures so as to close the pilot light contacts.

As the short circuited heater wire cools, it contracts and the contacts open. The magnetism drops to a low value and the main armature opens about 0,1 mm and secondairy armatures return to original positions.

The typical click-clack-sound is produced by the secondairy armature.

The contacts gap of the pilot contact is always approximately 0,4 mm.

If an indicatorlamp fails the current drawn is lower and the flashing frequency will rise. Additionally it may be that the secondary armature will not close at all, so no dashboard warning light will come on.

Hot-wire flasher circuit

The electronic flasher

The standard hot-wire flasher unit will not function correctly with an extra trailer load or modified as for used as warninglights (four lamps on at the same time).

However, it is recommend to use a universal electronic flasher.